Packaging design process

The development and production of a comprehensive packaging solution for the automotive and electrotechnical industries are the most challenging disciplines in industrial packaging where only the best will succeed. TART has been involved in this market for more than 25 years and has developed and created packaging for a wide range of business partners not only in the Czech Republic but also abroad. Most often to create this returnable or one-way packaging with higher added value several subsequent steps need to be followed.

To take all important aspects into account during the development and the manufacture of the packaging, TART has developed its own packaging analysis and development system, V.I.C.O.®, which means Value Inside - Checkpoint Outside. V.I.C.O.® sets and continuously monitors all priorities for specific packaging solutions in terms of product protection, packaging life, ecology, handling and logistics, information provided and, of course, total packaging costs.

Analysis

The cornerstone of the perfect packaging solution is a detailed input analysis. As a part of this phase TART experts identify customer requirements and expectations. They collect information about the packaged product, its protection, handling and storage requirements and are interested in manufacturing and logistics processes not only at the manufacturer itself but also throughout the logistics flow.

The key aspect is always the economy of the solution not only in terms of the final price of the packaging but also in terms of minimizing the costs of transport, storage and handling.

Design

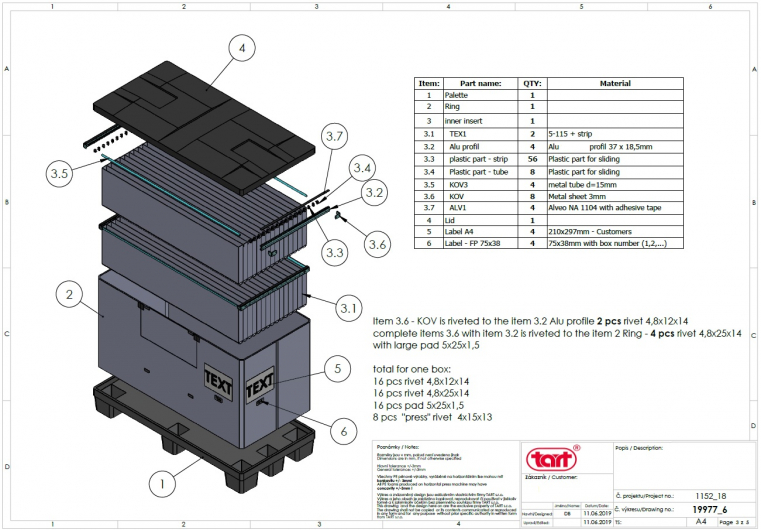

Based on the results of the analysis the final project of the optimal packaging solution is developed within the TART development centre, the ideal packaging concept is designed and fully functional samples are then produced.

Particular emphasis is placed on the speed of the entire development process so that the customer has the samples as quickly as possible.

Testing

Functional samples are tested not only within the development centre and the test laboratory but also in live operation. Various aspects of the packaging are verified such as level of protection of the packaged products, difficulty of handling and packaging process and durability of the packaging.

It is imperative that the designed packaging solution withstands real conditions and fully meets all customer requirements.

Production

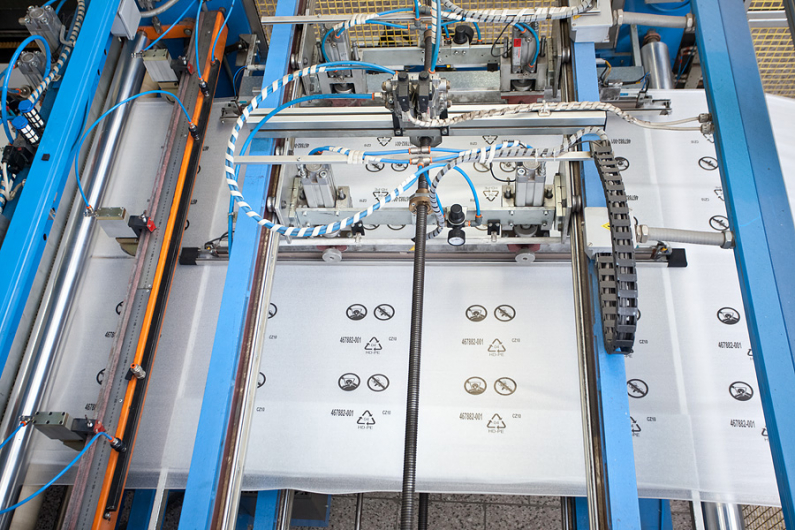

After testing and approval of prototypes, a phase of packaging production run follows. TART owns several manufacturing plants that specialize in the production of certain types of packaging and packaging materials.

Our offer includes, for example, cardboard boxes, plastic boxes with cushioning inserts, wooden packaging, interlocking partitions, foam custom cut-outs, protective self-adhesive foils, metal frames with textile materials and many other packaging solutions.

Thanks to modern equipment and top experts all packaging has a high quality of manufacturing.

Service

However, the process does not end with the production of packaging. There have been high demands on follow-up services especially recently.

Thanks to its own network of logistics and distribution centres and sophisticated logistics, TART manages even the most demanding customer requirements within Just In Time deliveries, guarantee of insurance stocks, kitting, etc.